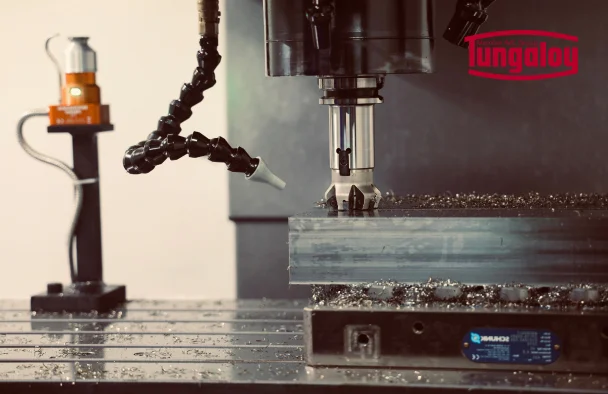

Metal Cutting and Clamping Technology

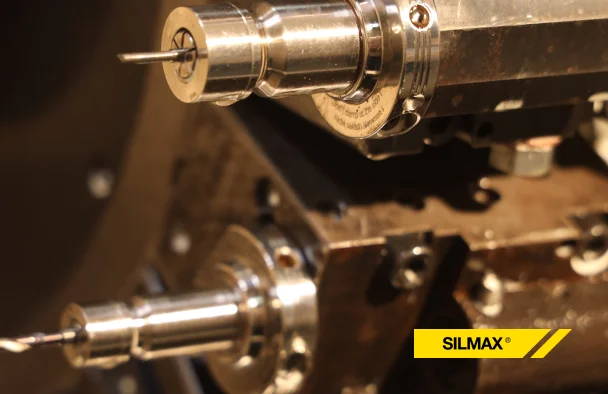

Silmax Spa SILMAX manufactures a wide range of standard and special, solid carbide and high-speed steel tools for roughing, semi-finishing and finishing metals and light alloys, according to UNI EN ISO and DIN standards and to the specific requirements of our customers.

200 Years of History

SILMAX is a leading enterprise in the production of a wide range of standard and special cutting tools with an over 200 year history. The company is based in Lanzo Torinese, in Piedmont. Our entire production process is carried out inhouse, in our factory of Lanzo Torinese. Silmax’s team is always ready to support its customers, thanks to more than 50 years of experience in its activity and its modern and dynamic organization.

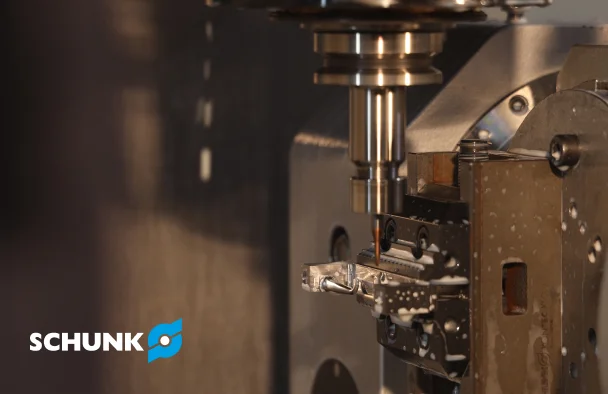

SCHUNK is a leading company in clamping technology, offering a wide range of innovative solutions for various machining applications. Their product lineup includes hydraulic expansion toolholders, magnetic clamping technology, stationary work holding systems, and lathe chucks. Schunk’s clamping devices are designed to provide high precision, reliability, and efficiency, enhancing productivity and ensuring the quality of machining operations. Their advanced clamping solutions often feature automated and intelligent systems to optimize setup times and improve overall performance in industrial environments.

Oemeta is a renowned manufacturer of high-performance lubricants and coolants specifically designed for the metalworking industry. Their product range includes water-miscible coolants, neat oils, and forming lubricants, all engineered to enhance machining efficiency, tool life, and surface quality. Oemeta focuses on creating environmentally friendly and sustainable solutions that reduce waste and improve workplace safety, making them a preferred choice for many manufacturing and machining operations worldwide.