The Company

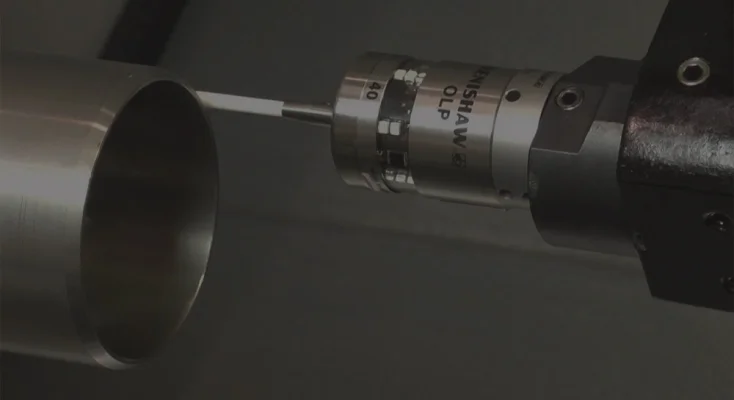

PMI Global Technologies is expertise in low and Medium volume complex part manufacturing and adds value to the components by executing Special process and Precision Assembly operations .PMI Global Technologies has been providing its clients total Product manufacturing solutions including engineering services since 2016. Strategically located in India, Precision CNC machining (Milling, Turning and Turn Mill operations) able to hold tolerances down to .0001 inch. Assembly of complex electro-mechanical subsystems.

Challenge

The Ti-6Al-4V alloy is an α–β titanium alloy that exhibits high strength, low density, and good corrosion resistance. It is one of the most commonly used titanium alloys. The joining of C/C and TiB whisker (TiBw) reinforced Ti-6Al-4V composite by brazing is more effective by using a brazing material consisting of Cu–Ni alloy and TiB2 than one consisting of only the Cu–Ni alloy. The shear joint strength is 56% higher for the former. The TiB2 particles in the brazing material react with Ti, which diffuses from the TiBw/Ti-6Al-4V composite, resulting in the formation of TiB whiskers in the brazing layer. The in situ synthesized TiB whiskers are uniformly distributed in the joint and provide reinforcement and decreased residual thermal stress.

Due to the machining complexity the current endmill gave a tool life of 400 components which resulted in lot of down time and a higher tool consumption.

Solution

The Titainox and Superalloys range represents the innovative proposal for machining stainless steels, titanium and superalloys, capable of achieving cutting parameters that are much higher than those offered by high-end items. The innovative superior-quality cutting edge, the specific rake angle surface treatment, together with Silmax 4S superfinishing process allow to combine an extraordinary finish (surface roughness below 1 micron), while maintaining the maximum cutting performance.

Result

The total tool life has increased by 4x thanks to the the PVD Balzers Latuma ® coating currently represents the best proposal for machining titanium and stainless steels. The total cost saving per annum is 3.50L approx.